Brands

Nikkiso Cryo

About the Company

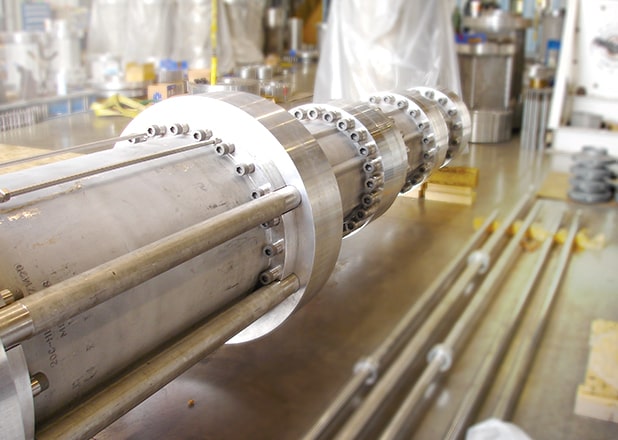

Nikkiso Cryo, Inc. is a leading supplier of cryogenic submerged electric motor pumps used in the liquefied gas industry. NCI’s innovative designs have resulted in the first application of high pressure pumps for use on regasification LNG carriers, the first and only cryogenic pumps installed on an LNG GBS, compact high flow pumps for the world’s largest FPSO under construction, as well as compact, higher speed pumps used for a variety of LNG, LPG and other applications.

Our History

Nikkiso Cryo is proud of our strong reputation for integrity – earned through our Technical Partnership approach that increases peace of mind for our customers. As a result, we enjoy a history of meeting specifications as well as delivering on time and on budget. Our Project Engineering leadership allows for seamless integration of Nikkiso Cryo equipment with our customer’s operating systems. Each customer is assigned a dedicated Project Manager for consistent, individualized care.